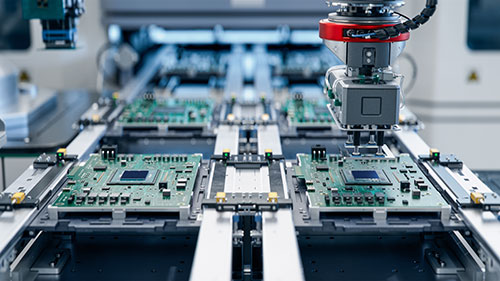

Fast and capable manufacturing test

Integrate XJTAG into your production line to streamline your testing and produce detailed test logs

High-speed adaptive testing

When you need to test the electronics you produce, XJRunner is there to run the projects produced by XJDeveloper. Easy to use, reliable and versatile, it gives clear pass/fail results to the operator, saving the details to formatted or plain-text logs for audit. You can run tests on multiple units in parallel and assign different privileges to users to allow some users to only run tests while giving others access to more information and features for troubleshooting.

XJRunner can run tests conditionally to optimise use of time on the production line, for example, only performing detailed tests if a high-level one fails, or skipping programming operations unless all previous tests have passed.

XJRunner includes XJTAG’s layout and schematic viewers and the diagnostics available from its testing allow technicians to quickly identify where on a PCB any problems have been found.

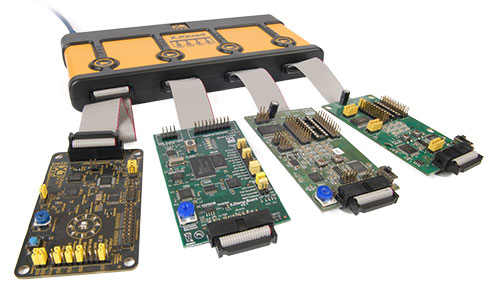

Powerful, flexible, reusable test equipment

When you’re using XJTAG, most of the data about your board is in the software, and very little is tied to the test fixture. This means tests can be easily updated or customised for different variants of a board on the fly and there is no need to build a new test fixture for every iteration of a board.

XJTAG’s XJLink test controllers are compact and portable, so you can easily move them between fixtures as required. Software licences can be stored in the controller so you don’t need to worry about licence management between computers.

Integrate with your test executives & ATE machines

XJLink test controllers are designed to be integrated into your production line and interface with other test equipment, controlling the test process and keeping detailed logs of the test results.

Various different form factors of XJLink are available to fit easily into complementary systems, including a PXI version for use with LabVIEW and TestStand, as well as cards for flying probe and in-circuit test machines from Keysight, SPEA and more.

Expert support provided by real engineers

XJTAG support provides everything you need to get your projects up and running: from video tutorials to a service converting your ODB++ files into a test-ready project.

Phone and email support are available if you have any issues. If you find a new device that isn’t covered by the XJTAG library, let us know – we regularly release updates to the library and can add new devices as required.